SPECIFIC RANGE OF CONNECTORS FOR SANCOL PP REINFORCED BUILDING EVACUATION TUBES Ø 100 WITH JOINT

For optimum evacuation of water outside buildings, the evacuation tubes must be assembled so that they ensure the seal and longevity of the network of pipes, even when there are changes in direction. If not installed correctly, the junctions between the tubes are sections where leaks, cracks or breaks tend to occur.

To accompany the movements of the ground, ATE has developed a range of reinforced connectors with joints of diameter 100 suited to the SANCOL SN4 or SN8 PVC tubes.

Reinforced PP connectors designed for outdoor use

Rain and waste water of a house must be directed to the public drain network or to an individual treatment installation on the plot if not connected to a collective system. In both cases, the evacuation of this water to a septic tank and/or a sewer must ensure there are no leaks and also the longevity of the network.

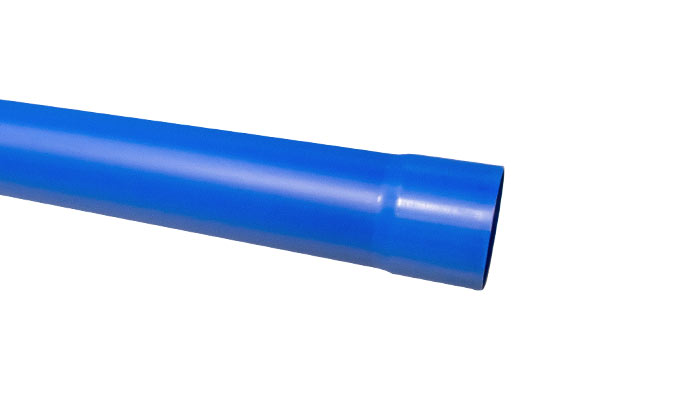

The first precaution is to choose PVC pipes designed to be buried and to resist constant crushing from the weight of the ground. The Sancol ATE Drainage tubes are SN4 or SN8 rated depending on their level of mechanical resistance. These tubes are connected with a joint and are not bonded, which allows them to accompany the natural movements of the ground.

For the connection of the SANCOL joint tubes, ATE Drainage has developed a range of connectors with joint, compliant with the NF EN 1451-1 standard, with SN4 mechanical resistance.

There are several types of connectors available: joint elbows of different angles, sleeves, threaded connectors, plugs, 45° Y, 87.5° Tee, to adapt to all angles and curves on the plot.

Guide marks to make installation easy

The connectors are fitted without bonding in 3 stages. The tube is first chamfered then a lubricant is applied to the end of the tube and to the connector joint. The tube is then inserted into the connector to the stop. The assembly of the connection is made easier with an alignment and insertion guide mark and an angle guide mark.

The tube is designed to facilitate installation, so that trial assembly is not needed and this saves considerable time. The tubes are assembled with joints and not bonded with glue to ensure the seal. Furthermore, this technique accompanies the natural movements of the ground, to reduce the risk of the system breaking.